I-Hydraulic Slewingyenza imishini esindayo ijikeleze ngokushelela nangokunembile ngokuguqula uketshezi olucindezelwe lube ukunyakaza kwemishini. Le nqubo incikei-hydraulicamandla, anikeza ukusebenza kahle okuphezulu-amaphampu we-hydraulic kulezi zinhlelo ngokuvamile afinyelela ukusebenza kahle okungama-75%. Ama-opharetha angancika kulobu buchwepheshe ngokuzungezisa okungaguquki, okulawulwayo ezinhlelweni ezifunayo.

Okuthathwayo Okubalulekile

- I-hydraulic slewing isebenzisa uketshezi olucindezelwe ukudala ukujikeleza okubushelelezi, okunembe emishinini esindayo, kuncike ezingxenyeni ezibalulekile ezifanaama-hydraulic motors, ama-slewing bears, amaphampu, nama-valve okulawula.

- Lolu hlelo luguqula amandla asebenza ngamanzi abe ngukunyakaza kwemishini kahle, anikeze itorque eqinile nokulawula okuhle, okusiza imishini ukuphatha imithwalo esindayo ngokuphepha nangokunembile.

- I-Hydraulic slewing ithuthukisa ukwethembeka, inciphisa ukusetshenziswa kwamandla, futhi yehlise nezidingo zokulondolozwa, ikwenze ifaneleke kuma-cranes, ama-excavators, izinjini zomoya, nemishini yasolwandle.

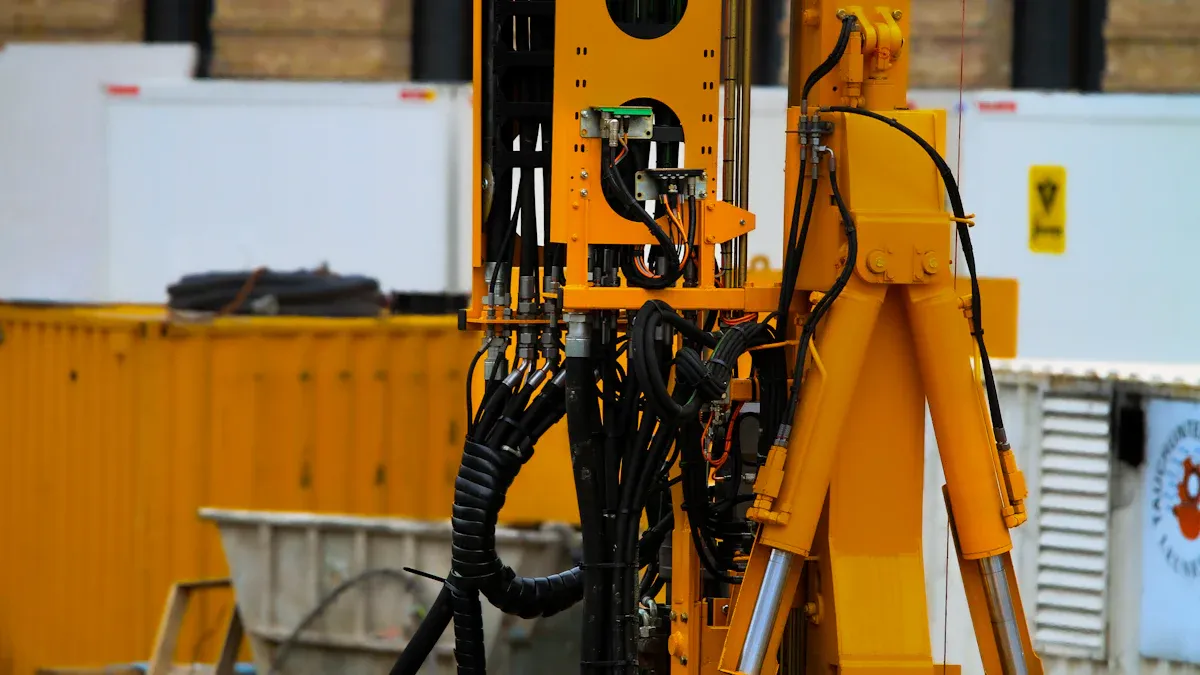

Izingxenye zeHydraulic Slewing System

I-Hydraulic Motor

Ii-hydraulic motoryakha umnyombo weHydraulic Slewing system. Iguqula amandla we-hydraulic abe ukuzungezisa kwemishini. Le moto ilawula isivinini kanye netorque edingekayo ukuze kuhambe kahle. Ucwaningo lukhombisa ukuthi ukusebenza kwe-hydraulic motor kuncike ekutheni ilawula kahle kangakanani isiqondiso, ingcindezi, nokugeleza. Onjiniyela basebenzisa amasu okulawula athuthukile ukuze bandise isivinini netorque. Ucwaningo luphinde lugqamise ukubaluleka kokusebenza kahle kwamandla kanye nokuzinza kwesistimu ekubulaweni kwezinhlelo zokusebenza. Ngokuqonda lezi zici, opharetha bangafinyelela ukuzungezisa okunembe nokuthembekile.

I-Slewing Bearing

I-slewing bear isekela isakhiwo esijikelezayo futhi iphethe imithwalo esindayo. Ivumela umshini ukuthi ujike kahle ngenkathi uphethe i-axial, i-radial, kanye namandla okugumbuqela. Ucwaningo lwezibalo lusebenzisa amamodeli afana nokusatshalaliswa kwe-Weibull kanye nethiyori yokuxhumana ka-Hertzian ukubikezela ubude bempilo namandla omthwalo wamabheringi okuhlaba. Lolu cwaningo lubonisa ukuthi iringi egxilile yebheringi igqoka ngokushesha kuneringi ezungezayo. Onjiniyela basebenzisa izindlela zokuhlola ezithuthukile ukuze balinganisele ukuphila futhi baqinisekise ukuphepha emishinini esindayo njengama-cranes nama-wind turbines.

Iphampu yeHydraulic kanye neReservoir

Iiphampu ye-hydraulicihlinzeka ngoketshezi olucindezelwe ohlelweni, kuyilapho indawo yokugcina amanzi igcina uwoyela we-hydraulic. Amaphampu ekhwalithi ephezulu kuma-Hydraulic Slewing systems ngokuvamile afinyelela amazinga okusebenza kahle angaphezu kuka-90%. Imiklamo yesimanje yokugcina amanzi inciphisa ubukhulu nesisindo, okwenza uhlelo lusebenze kahle. Abasebenzisi kufanele bahlole amazinga oketshezi njalo futhi basebenzise uketshezi oluhlanzekile, olugunyazwe ngumkhiqizi. Imisebenzi yokunakekela efana nokushintsha izihlungi namafutha isiza ukuvimbela ukungcoliswa kanye nokwelula impilo yesistimu. Ithebula elingezansi liqhathanisa imiklamo yedamu yendabuko neyesimanje:

| Isici | I-Traditional Reservoir | I-Modern Reservoir |

|---|---|---|

| Usayizi | 3–5x ukugeleza kwepompo | 1:1 ngokugeleza kwepompo |

| Isisindo | Kunzima | Kufika ku-80% ukulula |

| Umthamo Wamafutha | Okukhulu | Kwehliswe ngo-80% |

Ama-valve nama-Hoses okulawula

Amavalvu okulawula kanye namapayipi aqondisa ukugeleza koketshezi olunamanzi kulo lonke uhlelo. Ama-valve athembekile agcina ukucindezela okuzinzile futhi aqinisekise ukusebenza okuphephile. Ucwaningo lwama-valve dynamics lubonisa ukuthi ama-valve aklanywe kahle aphatha izinguquko zengcindezi ngaphandle kokulahlekelwa ukuzinza. Izigxivizo zekhwalithi zivimbela ukuvuza futhi zigcine ukungcola kungangeni. Amapayipi ahanjiswe ngendlela efanele nokuxhumana okuvikelekile kusiza ukugcina ubuqotho besistimu. Onjiniyela bakhetha izinto eziqinile zamapayipi nama-seal ukuze zimelane nezimo ezimbi kakhulu futhi zinciphise ukuguga.

I-Hydraulic Slewing Working Principle

Ukusebenza Kwesinyathelo Ngesinyathelo

Amasistimu we-Hydraulic Slewinglandela ukulandelana okunembile ukuze uzuze ukuzungezisa okubushelelezi nokulawulwayo. Inqubo iqala lapho opharetha evula i-lever yokulawula. Lesi senzo sithumela uketshezi olusebenza ngomfutho we-hydraulic olusuka epompo ngamavalvu okulawula namapayipi ukuya enjinini edonsa amanzi. Injini ithola la mandla bese iqala ukujikeleza, iphendulela i-slewing bear kanye nemishini enamathiselwe.

Onjiniyela bavame ukulungisa i-valve yokulawula amandla endaweni engathathi hlangothi ngaphambi kokulinganisa izingcindezi zokungena nokuphumayo. Bese bebala amandla okufaka nawokukhiphayo, kanye nokusebenza kahle kwesistimu. Ngokuvala kancane kancane imbobo yokudonsa amanzi ngezinyathelo ezincane, babona ukuthi indawo ye-valve ithinta kanjani ukudluliswa kwamandla. Le ndlela ibonisa indima ye-valve njenge-clutch, evumela ukulawula okucushwe kahle phakathi nemisebenzi yokubulala. Kwamanye amasistimu athuthukile, ukulandelana kuhlanganisa ukuhlaziya ukubaluleka kwengxenye nokuthuthukisa ukunakekelwa ukuze kuqinisekiswe ukwethembeka. Isinyathelo ngasinye, ukusuka ekufakweni kwamandla kuya ekuphatheni ukulayisha, sinikela ekusebenzeni okuzinzile nokusebenza kahle kwemishini yokuSletshwa kweHydraulic.

Ukudluliswa kwamandla kanye nokuguqulwa

Amasistimu we-Hydraulic Slewingzisebenza kahle kakhulu ekuguquleni amandla asebenza ngamanzi abe ngumshini wokuzungezisa. Iphampu ye-hydraulic iletha uwoyela ocindezelwe enjinini, ebese iguqula la mandla abe yitorque. I-slewing bear isakaza le torque, ivumela imishini ukuthi ijikeleze ngaphansi kwemithwalo esindayo. Ukusebenza kahle kwale nqubo kuncike ezintweni eziningana, njengokucindezela kwe-accumulator nevolumu.

Ithiphu:Ukwenyusa ingcindezi yokuqala ye-accumulator noma ivolumu kungehlisa isidingo samandla esiphezulu futhi kunciphise ukusetshenziswa kwamandla ngesikhathi sokubulala.

Ithebula elingezansi ligqamisa ukuthi amapharamitha ahlukene awathinta kanjani amandla kanye nokusetshenziswa kwamandla ezinhlelweni zokuhlaba:

| Ipharamitha | Isimo/Inani | Umthelela Ekudleni Amandla Emoto Nokusetshenziswa Kwamandla |

|---|---|---|

| I-Accumulator Yokuqala Ingcindezi | Phezulu | Amandla aphezulu ayancipha, ukusetshenziswa kwamandla kuyehla |

| Ivolumu ye-Accumulator | 350–500 L | Ivolumu enkulu yehlisa amandla aphezulu kanye nokusetshenziswa kwamandla |

| IHybrid vs Pure Electric System | Uhlelo lweHybrid | Amandla aphezulu kanye nokusetshenziswa kwamandla kwehliswe kufika ku-29.6% |

| Hoisting Motor Peak Power | Ugesi ohlanzekile: 600 kW | I-Hybrid: 380 kW (ukunciphisa ngo-36.7%) |

| Ukusetshenziswa kwamandla ngomjikelezo ngamunye | Ugesi omsulwa: 4332 kJ | Ingxubevange: 3048 kJ (29.6% ukonga amandla) |

Amasistimu we-Hybrid athuthukisa ukusebenza kahle ngokuthola amandla ngesikhathi sokuncipha futhi aphinde asetshenziswe ngesikhathi sokusheshisa. Le ndlela inciphisa kokubili izidingo zamandla aphezulu kanye nokusetshenziswa kwamandla jikelele, okwenza amasistimu e-Hydraulic Slewing asebenze kahle kakhulu ekusetshenzisweni komsebenzi osindayo.

Ukulawula nokunemba

Izinhlelo zesimanje zeHydraulic Slewing ziletha ukulawula okukhethekile nokunemba. Izixazululo zokulawula okwesibili zinika amandla ukunemba okuphezulu nokuphendula okuguquguqukayo, ngisho nasezinsizeni ezinkulu ezifana nama-cranes ahambayo anezindandatho zokuhlaba ezingafika kumamitha angu-50 ububanzi. Lawa masistimu agcina ukwethembeka nokusebenza kahle kwamandla ngenkathi ehlangabezana nezindinganiso eziqinile zokunemba.

Amasu okulawula athuthukile, njenge-PID engaqondile kanye nokulawula okubikezela imodeli yenethiwekhi ye-neural, athuthukise kakhulu ukunemba kokuma. Isibonelo, amanye amasistimu anciphise amaphutha okumisa ukusuka ku-62 mm kuya phakathi kuka-10 mm. Lokhu kuthuthukiswa kuphinde kuholele ekongeni ugesi, ngokuncipha okufika ku-15.35% ngaphansi kwezimo zokungalayishi.

Ama-bearings anembe kakhulu adlala indima ebalulekile ekugcineni ukunemba. Abakhiqizi basebenzisa imiklamo ekhethekile yomjaho kanye nezinto ezisebenza ngamandla ukuze baqinisekise ukusebenza okungaguquki, ngisho nangaphansi kwemithwalo esindayo nezimo ezimbi kakhulu. Le nhlanganisela yezilawuli ezithuthukisiwe nezingxenye eziqinile ivumela amasistimu we-Hydraulic Slewing ukuthi afinyelele ukunyakaza okubushelelezi, okunembile okubalulekile emisebenzini enzima yezimboni.

Izinzuzo kanye nokusetshenziswa kweHydraulic Slewing

Izinzuzo Eziyinhloko

I-Hydraulic Slewinginikeza izinzuzo ezimbalwa ezibalulekile zemishini esindayo. Uhlelo luhlinzeka ngokujikeleza okushelelayo nokulawulwayo, okusiza opharetha babeke imishini ngokunemba okuphezulu. Amasistimu we-Hydraulic Slewing aphatha imithwalo emikhulu kalula. Baletha i-torque eqinile, ebenza balungele imisebenzi enzima. Ubuchwepheshe buphinde buthuthukise ukuphepha ngokuvumela ukunyakaza okunembile, ngisho nasezindaweni eziqinile.

Onjiniyela abaningi bayakwazisa ukwethembeka kweHydraulic Slewing. Uhlelo lusebenza kahle ezindaweni ezinokhahlo, njengeziza zokwakha noma amapulatifomu angaphesheya kwezilwandle. Izidingo zokunakekela zihlala ziphansi ngoba izingxenye zimelana nokuguga nokulimala. Ama-opharetha angathemba ukuthi isistimu izosebenza ngokungaguquki esikhathini eside.

Qaphela:Amasistimu we-Hydraulic Slewing ngokuvamile anciphisa ukusetshenziswa kwamandla kanye nezindleko zokusebenza. Lokhu kusebenza kahle kusiza izinkampani ukuthi zonge imali futhi zivikele imvelo.

Ukusetshenziswa Okuvamile Emishinini

I-Hydraulic Slewing ivela ezinhlotsheni eziningi zemishini esindayo. Uhlu olulandelayo lubonisa ezinye izinhlelo zokusebenza ezivamile:

- Ama-Cranes asebenzisa i-Hydraulic Slewing ukuze ajikelezise ama-boom awo futhi aphakamise imithwalo esindayo.

- Ama-excavators athembele ohlelweni ukuze aguqule izakhiwo zawo ezingaphezulu zokumba nokulahla.

- Izinjini zomoya zisebenzisa ama-slewing drives ukulungisa indlela yama-blades.

- Imikhumbi yasolwandle isebenzisa i-Hydraulic Slewing emishinini yamadekhi namawintshi.

- Izimoto zokwakha, njengamaphampu kakhonkolo nezinkundla zasemoyeni, zisebenzisa isistimu ukuze zimise kahle.

Ithebula elingezansi ligqamisa imishini ejwayelekile nemisebenzi yayo yokubulala:

| Uhlobo Lomshini | Slewing Umsebenzi |

|---|---|

| I-Crane | Ukujikeleza kwe-Boom |

| I-Excavator | Ukuphenduka kwesakhiwo esiphezulu |

| I-Wind Turbine | Ukulawula isiqondiso se-blade |

| Umkhumbi Wasolwandle | Ukunyakaza kwemishini yedekhi |

| Ukhonkolo Pump Truck | Ukuma kwe-Boom |

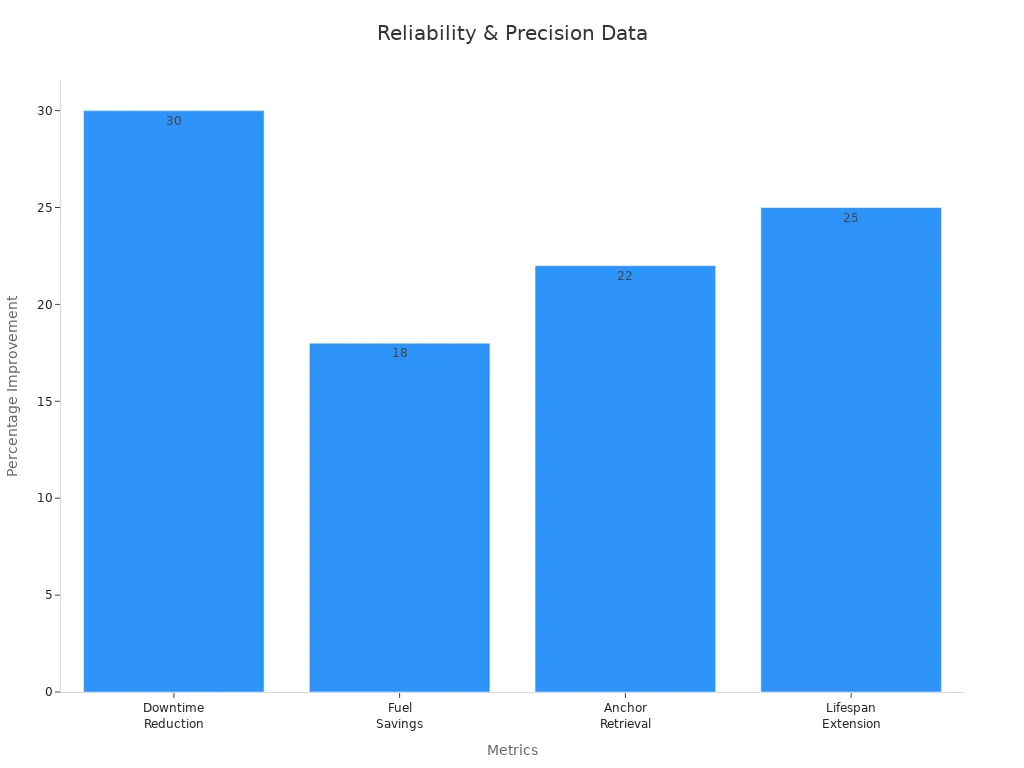

Amasistimu wokujula nge-Hydraulic abeka izindinganiso ezintsha zokuthembeka nokunemba kumishini esindayo. Abasebenzisi babika ukwehliswa ngo-30% kwesikhathi sokungasebenzi kanye no-18% ukonga uphethiloli eminyakeni emithathu.

| Incazelo Yemethrikhi / Yokuhlola | Umphumela / Ukuthuthukiswa |

|---|---|

| Ukunciphisa isikhathi sokuphumula kumasistimu we-hydraulic | 30% yehla |

| Ukonga uphethiloli kwezokuthutha zasolwandle | 18% yokonga eminyakeni emi-3 |

| Isivinini sokubuyisa ihange phakathi neziphepho | 22% ngokushesha |

| Izigameko zokuhluleka kwezimoto emikhunjini yasolwandle | Ukwehluleka kweqanda eminyakeni emi-3 emikhunjini eyi-12 |

| Ukusebenza okuqhubekayo kwamaphampu egiya le-hydraulic | Amahora angu-8,000 ngaphandle kokulahlekelwa ukusebenza |

| Ukusebenza kahle kwewintshi ye-Hydraulic | Kufika ku-95% |

| Isandiso sesikhathi sokuphila ngenxa yezinto eziqinisiwe | 25% ubude bempilo |

| Ibanga lokushisa elisebenzayo | -40°F kuya ku-300°F |

Ubunjiniyela obuthuthukisiwe, okufaka phakathi ukuhlaziya okulinganiselwe, kuqinisekisa ukubikezela okunembile kwengcindezi nokusebenza okuphephile. Amamodeli ezibalo asiza ukuthuthukisa ukulungiswa, ukusekela ukulawula okunembayo ezindaweni zezimboni.

FAQ

Kusetshenziselwani ukucwiliswa nge-hydraulic?

Ukushaya nge-Hydraulicizungezisa amathuluzi asindayo, njengama-cranes nama-excavators. Ama-opharetha ayisebenzisela ukuma okunembile kanye nokunyakaza okushelelayo embonini yokwakha, yasolwandle, neyamandla.

Ngabe isebenza kanjani i-hydraulic slewing bear?

I-slewing bear isekela isakhiwo esijikelezayo. Iphatha imithwalo esindayo futhi ivumela ukuzungezisa okubushelelezi, okulawulwayo ngokusabalalisa amandla ngokulinganayo kuwo wonke amasongo awo kanye nezinto ezigingqayo.

Ngabe opharetha kufanele bagcine kangaki amasistimu wokujula osebenza nge-hydraulic?

Ama-opharetha kufanele ahlole amazinga oketshezi futhi ahlole ukuvuza masonto onke. Ukunakekelwa okuvamile, okufana nezinguquko zokuhlunga nokushintshwa kukawoyela, kusiza ukuqinisekisa ukusebenza okuthembekile futhi kunwebe impilo yesistimu.

Isikhathi sokuthumela: Jul-06-2025